When it comes to mounting an engine on an engine stand, knowing the correct bolt size is crucial. This ensures that your engine is securely attached and eliminates any risks of accidents or damage. In this article, we will discuss the necessary steps to find the right bolt size for your engine stand.

Tools Needed

Before you begin, make sure you have the following tools:

- Wrench

- Tape Measure

Measuring Your Mount

The first step is to measure the mounting holes on your engine stand. These are typically found at the flywheel end of the engine. Using a tape measure, measure the diameter of the mounting holes.

Credit: www.mkivsupra.net

Credit: www.ictbillet.com

Finding the Right Bolt Size

Once you have the measurements, you can determine the correct bolt size. Most engine stands use either 3/8″ or 1/2″ bolts. Check the manual for your specific engine stand to confirm the recommended bolt size.

Installing the Mount

Now that you have the correct bolt size, it’s time to install the mount. Attach the engine stand mount to the engine block using the appropriate bolts. Make sure to tighten them securely to avoid any movement during the engine mounting process.

Benefits of Engine Stand Mounting

Mounting an engine on an engine stand offers several benefits, including:

- Easy access to all sides of the engine for maintenance and repairs.

- Safe and secure storage of the engine during off-vehicle work.

- Convenient rotation of the engine for better accessibility.

Where to Find Engine Stand Bolts

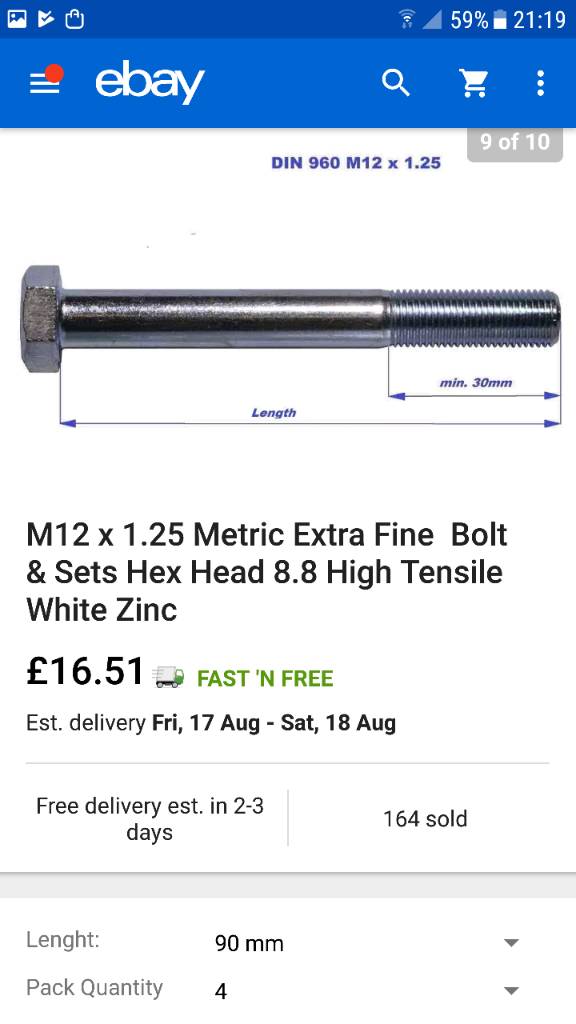

If you need to purchase engine stand bolts, there are several options available. Here are a few places where you can find them:

Frequently Asked Questions For What Size Bolts For Engine Stand

How Are Engines Mounted To Engine Stands?

Engines are mounted to engine stands by adjusting the arms on the stand’s head to reach different positions. Generally, the engine is mounted at the flywheel end using four holes that the transmission attaches to. It is important to choose a well-constructed and durable engine stand that is rated for the size and weight of the engine.

The stand may also have additional features such as lockable mounts, swiveling wheels, adjustable arms, and geared cranks for easier rotation.

What Size Are The Bolts On A Chevy Bell Housing?

The bolts on a Chevy bell housing are typically of two sizes: 3/8″ and 7/16″. These bolts are used to mount the transmission to the bell housing.

What Are The Measurements For An Engine Stand?

The measurements for an engine stand may vary depending on the specific model and brand. It is best to consult the manufacturer’s instructions or product specifications for accurate measurements. Engine stands typically have adjustable arms to accommodate different engine sizes.

Choose a well-constructed and durable stand suitable for the size and weight of the engine you will be mounting.

How Do I Choose An Engine Stand?

When choosing an engine stand, consider the following factors: 1. Look for a well-constructed and durable product that can support the size and weight of your engine. 2. Opt for stands that have features like lockable mounts, swiveling wheels, adjustable arms, and geared cranks for easier rotation.

3. Ensure that the stand has the appropriate bolt sizes to securely mount your engine. 4. Check for compatibility with your specific engine brand (e. g. , Small Block Chevy, Big Block Chevy). 5. Consider purchasing engine stand bolt kits that offer different sizes to fit various brands of stands.

What Are The Standard Bolt Sizes For Mounting An Engine To A Stand?

To properly mount an engine to a stand, you’ll generally need four bolts with specific sizes. The standard bolt sizes are typically 3/8 inch or 10mm.

Conclusion

Choosing the right bolt size for your engine stand is essential for a secure and stable engine mounting. Make sure to measure the mounting holes accurately and use the recommended bolt size provided by your engine stand manufacturer. By following these steps, you can safely mount your engine and enjoy the benefits of easy access and maintenance.