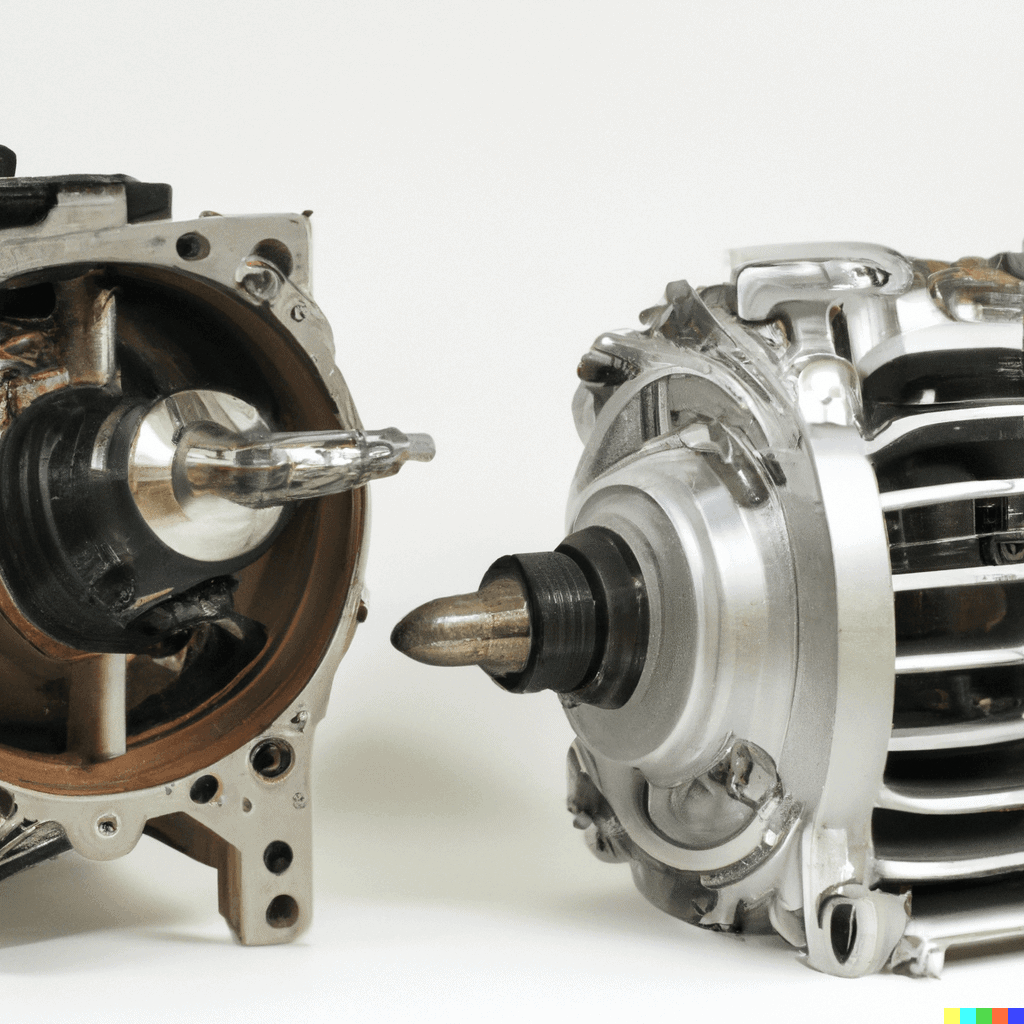

An alternator is an essential component of a car’s electrical system. It generates electricity and charges the battery while the engine is running. Over time, an alternator may fail or become less efficient, resulting in a need for repair or replacement.

Credit: uchanics.ca

Can I rebuild an alternator myself?

Yes, you can rebuild an alternator yourself if you’re tight on cash or enjoy DIY projects. Rebuilding an alternator involves replacing worn-out components such as bearings, brushes, and voltage regulators. It’s a cost-effective option if the major components are still in good condition.

How much does it cost to remanufacture an alternator?

The cost of remanufacturing an alternator can vary depending on the specific condition and the parts needed for replacement. However, rebuilding an alternator is generally cheaper than buying a new one.

Process Of Rebuilding An Alternator

The process of rebuilding an alternator involves several steps:

- Remove the voltage regulator by unscrewing the bottom brush assembly.

- Remove the screw that holds the lead into the grounding screw.

- Disassemble the alternator, taking care to remember the order and position of the components.

- Inspect each component, such as the stator and brush holder, for signs of wear or damage.

- Replace worn-out parts, including bearings, brushes, and voltage regulators, with new ones.

- Clean the alternator’s housing and other components using a suitable cleaning agent.

- Reassemble the alternator, making sure to follow the correct order and position of the components.

- Test the rebuilt alternator on a test bench or by installing it back into the vehicle.

Benefits of rebuilding an alternator

Rebuilding an alternator offers several advantages:

- Cost savings: Rebuilding an alternator is generally cheaper than buying a new one.

- Environmentally friendly: By refurbishing and reusing an existing alternator, you reduce waste.

- Availability of parts: It’s often easier to find replacement parts for rebuilding an alternator than for buying a new one.

- Personal satisfaction: Rebuilding an alternator yourself can be a rewarding project and give you a sense of accomplishment.

DIY videos on rebuilding an alternator

If you’re interested in rebuilding an alternator, there are many helpful DIY videos available online. Here are a few examples:

| Video Title | Duration |

|---|---|

| How to Repair Your Own Alternator (With Simple Tools) | 10:35 |

| How to Rebuild Alternator… and Test It! | 25:32 |

| Alternator Rebuild | 32:46 |

| How to Rebuild an AD Series GM Alternator | 24:58 |

These videos provide step-by-step instructions on disassembling, inspecting, and rebuilding different types of alternators. Watching them can help you understand the process and gain confidence in rebuilding your own alternator.

Conclusion

Remanufacturing an alternator is a cost-effective option for repairing a faulty or inefficient alternator. By rebuilding an alternator yourself, you can save money, reduce waste, and gain personal satisfaction. With the help of DIY videos and the right tools, you can successfully complete the rebuilding process and extend the life of your alternator.

Frequently Asked Questions On How To Remanufacture An Alternator

Can I Rebuild An Alternator Myself?

Yes, you can rebuild an alternator yourself. It’s a straightforward process to fix, and if you’re on a tight budget, repairing it yourself can save you money. Most car alternators are designed to be easily accessible for maintenance. Rebuilding involves replacing worn-out components like bearings, brushes, and voltage regulators.

It can be a cost-effective option if the major parts are still in good condition.

How Much Does It Cost To Remanufacture An Alternator?

The cost to remanufacture an alternator varies depending on the specific condition of the alternator. Rebuilding involves replacing worn-out components like bearings and brushes, which can be a cost-effective option if major components are still in good condition. The exact cost will depend on the extent of repairs needed.

How Do They Refurbish Alternator?

Refurbishing an alternator involves replacing only the parts that are no longer functioning, making it just as reliable as a new alternator. The process includes disassembling the old alternator, sandblasting the outer shells, resurfacing the contact surfaces of the spinning part called the commutator, and replacing the bearings at the ends.

Rebuilding the alternator can be a cheaper option compared to buying a new one, especially if the major components are still in good condition.

Is It Cheaper To Rebuild A Alternator Or Buy A New One?

Rebuilding or buying a new alternator depends on its condition. If the major components are still in good shape, rebuilding by replacing worn-out parts like bearings and brushes can be cost-effective. However, if the alternator has significant damage or wear, buying a new one may be a better option.

Can I Remanufacture An Alternator Myself?

Yes, remanufacturing an alternator is a simple task that can be done by yourself, saving you money and time.

How Much Does It Cost To Remanufacture An Alternator?

The cost of remanufacturing an alternator can vary depending on the model and brand, but it is generally more affordable compared to buying a new one.